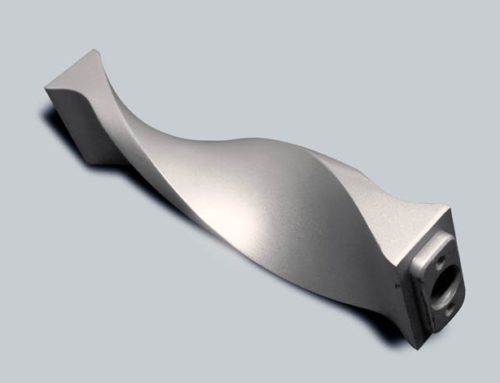

Metal injection molding is a powder metallurgy process used for manufacturing metal parts. Although metal injection molding uses powder metal, it is nothing like conventional powder metal processing. The metal powders used in metal injection molding are 10-100 times smaller than in powder metal processes. Also, the end product of metal injection molding is much higher in density. Applications for metal Injection Molding China parts include surgical tools, automotive locks and actuators, firearm components, computer hard disk drives and electrical connectors.

Process of Metal Injection Molding

Metal injection molding is a fast growing manufacturing method that bridges the gap between the technology up gradation and costs involved. The metal injection molding process involves five steps, mixing, injection molding, de binding, sintering, and part finishing.

In the mixing step, metallic powders, selected for their strengths and inherent abilities such as impact strength, high and low temperature characteristics, wear resistance characteristics, machine ability, and hardness, are mixed, often with a binding agent. By mixing powders, the goal is to create a composite with the strengths and benefits of all the incorporated metals, while offsetting the independent weaknesses.

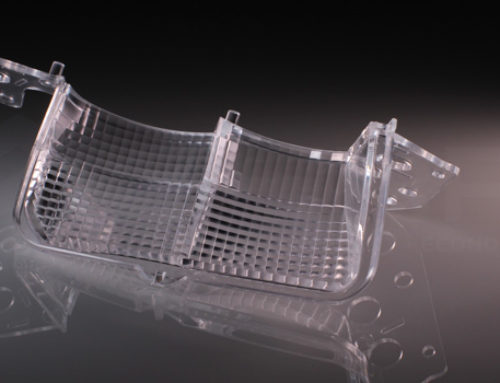

Once the powders are mixed, a “feedstock” is produced. This feedstock is injected into Injection Molding China in the same way that plastic or rubber injection molding is performed. The part that emerges from the injection molding stage is referred to as a “green” part.

In the de binding stage of metal injection molding, the green part is immersed in a water bath to remove the binder, which has entered into the part matrix. In cross-linking, the de bound green part is exposed to ultraviolet light which thermo sets the binding agents used with the metal powders.

Once the de binding stage has been completed, the part is placed into a furnace and heated to over 2000 degree Fahrenheit. This process, called sintering, fuses the metal parts into a solid shape. Finally, the sintered piece is sent to a finished stage where burrs and surface imperfections are removed and the finished part can be shipped.

Advantages of Metal Injection Molding

– High Shape Complexity

– Low Cost

– Tight Tolerances

– High Density

– High Performance

Uses of Metal Injection Molding

The technology excels at applications that require shape complexity and high final properties, such as high strength and density, excellent magnetic permeability, high temperature strength, corrosion resistance, and thermal conductivity in applications that cannot be fulfilled by plastics or light metal alloys. Metal injection molding is thus best for some of the following uses viz. making of microelectronic packaging, automotive sensors and actuators, hand tools and hardware, computer heat dissipation devices, oil well drilling tools, aerospace and engine fuel components.

To Sum Up

Metal Injection Molding China can provide a substantial cost savings over conventional metal machining options. Metal injection molding parts have high densities and mechanical properties approaching those of forged or machined components. Metal injection molding process can produce more complex parts than either investment casting or traditional press and sinter techniques.