The technological innovations, such as rapid prototype China, are almost advancing every chance of step it takes. Every day, a lot of new inventions are being presented to the people. Today, it is very much easy to picture out things that one creates in mind. With the help of those 3d printers, one can easily visualize the patterns and structures of a project in reality. Traditionally, engineers and architects used to draw the project structure on the paper, called the blueprint, and they will build a small miniature version of their project. Today, the structure and patterns will be made using the computers and the exact features can now be printed. More precise than the 3D printer is the rapid prototyping machine. It has been widely used today by the professionals like the architects and engineers and any other big companies.

Rapid prototyping machine is made up of different machines that create a 3D version of the scaled models. It has been presented more than a decade and up to now; it has been constantly renewing the features it can provide. The conversion of the data into the prototype machine is the same process that is happening when one encodes a data into the computer and prints the data using the printer. The finalized file of the model is being generated using the software called CAD, and the data is then transformed into a file with an STL extension. Rapid prototype machines in China are able to decode the data using the STL file and segmenting the data into different layers.

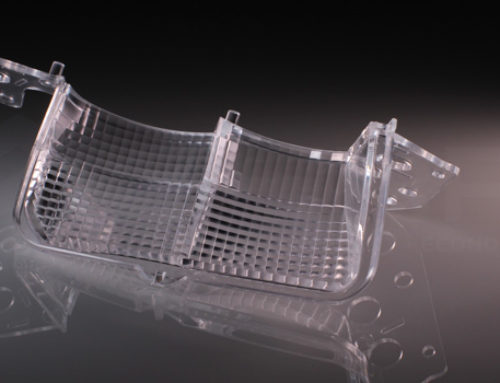

Stereo-lithography, solid ground curing, and used deposition modeling, are the names being adhered on it. Resins are the main component being used in the entire process. Resin is a viscous substance made through the process of polymerization, and the process of rapid prototyping machine begins with the stereo-lithography. Stereo-lithography is the process wherein the photosensitive resin was being hardened by the laser beam. As the name implies, solid ground curing, restores the resin with the ultraviolet rays. While the used deposition modeling, is the process where melted polymers are being used for the support of the different layers which can be found the structure. All of these processes are the actual occurrence that happens within the machine.

Today, a lot of various professions are now using this type of machine. It has been found useful since it could create a 3d image that can clearly visualize the project that one wishes to present. The rapid prototype machine can also save time, effort and money. It saves time for the fact that instead of creating the scaled models for almost months, it can possible happen in days. Although this type of machine causes more than hundred of thousand dollars, still it can reduce the overall expenditures of the materials used for traditional scale modeling. In addition, low material wastes are also one of the good advantages it will create to the business, the scaled models made by the rapid prototype machines increase successful communication between engineers, product designers and marketing departments. Hence, increase collaboration between them is expected.